Chocolate

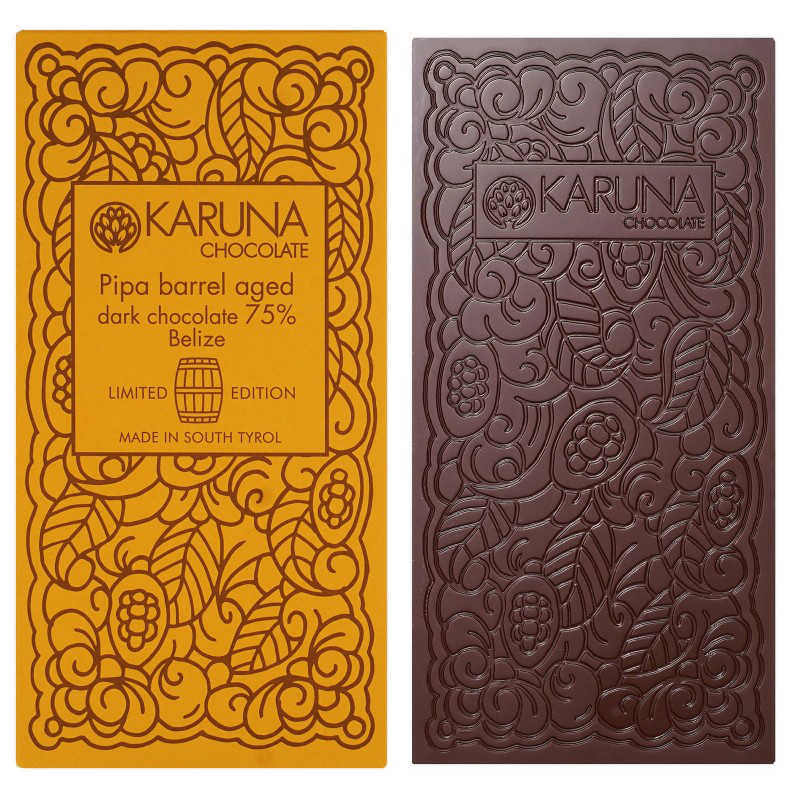

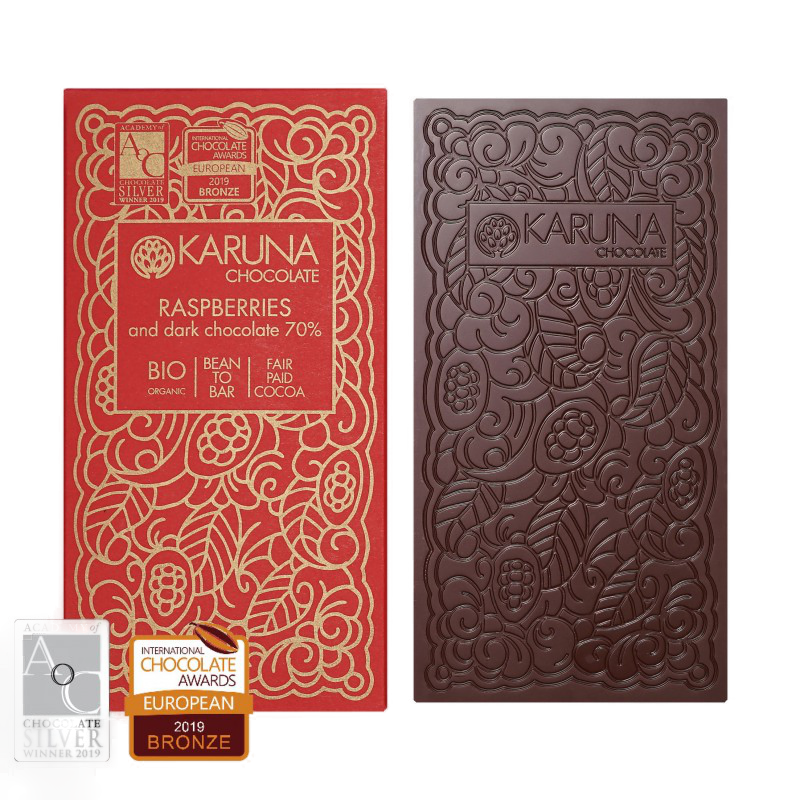

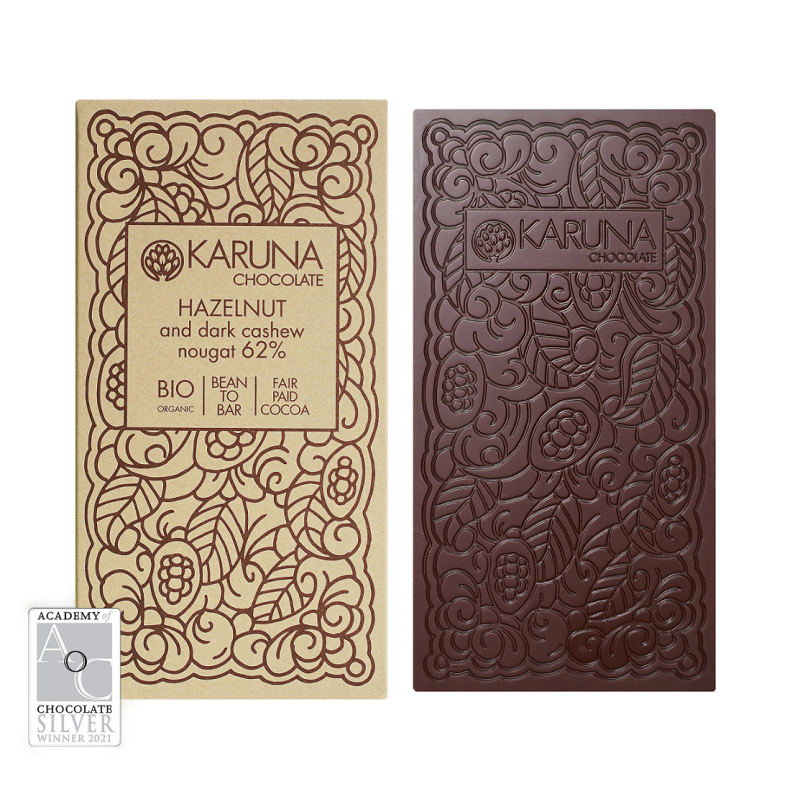

Chocolate from South Tyrol – handcrafted by Karuna, made with pure ingredients and full-bodied flavour.

60 (€0.18/)

60 (€0.14/)

60 (€0.14/)

60 (€0.14/)

50 (€0.16/)

60 (€0.14/)

50 (€0.16/)

SOUTH TYROLEAN CHOCOLATE

Artisanal quality with character

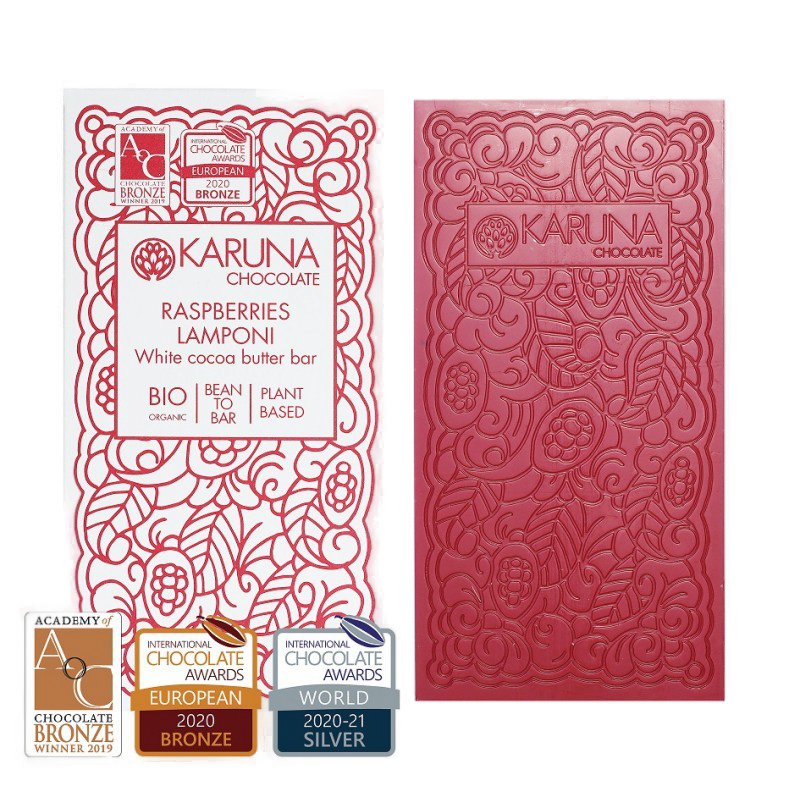

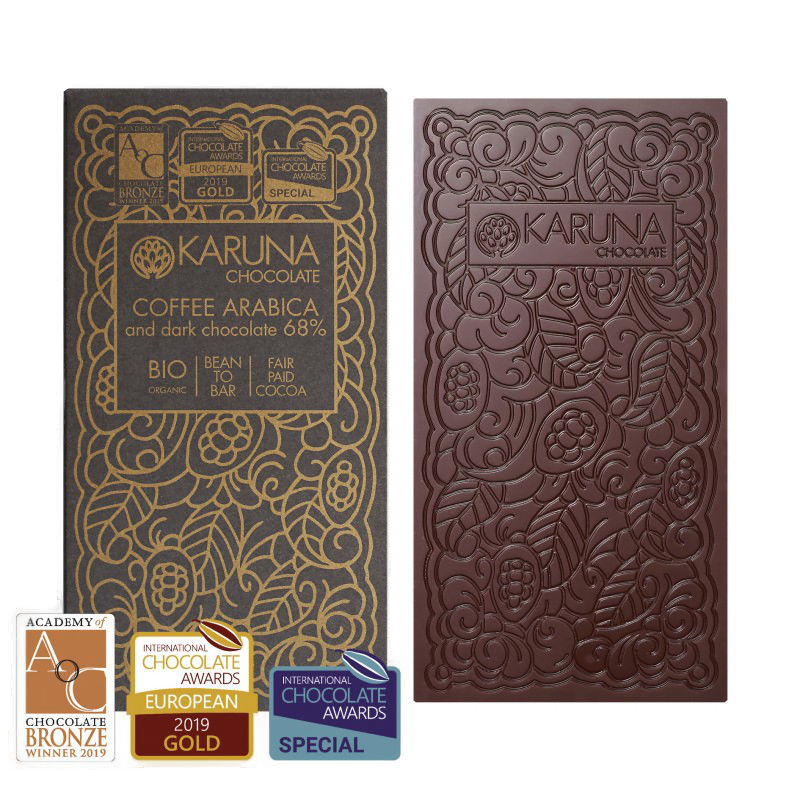

Chocolate from South Tyrol combines tradition, craftsmanship and pure indulgence. With great attention to detail, the Karuna manufactory is dedicated to producing high-quality chocolate that stands out for its naturalness and intense flavour. The secret lies in the selection of fine cocoa varieties and gentle processing. By deliberately avoiding artificial additives, Karuna creates chocolates that preserve their authentic character – creamy, aromatic and full of taste.

Every bar of Karuna chocolate is a piece of South Tyrolean craftsmanship, embodying purity, sustainability and refined flavour diversity. In addition to classic varieties, the manufactory delights with creations such as fruity raspberry, the elegant combination of almond & orange, or exquisite cashew nougat with hazelnuts. Enjoyed as a fine treat, with coffee, or as a dessert companion – Karuna chocolate blends Alpine authenticity with Mediterranean lightness, turning every indulgent moment into something truly special.